Pigging System / Product Recovery System

Pigging System / Product Recovery System is a vital and most beneficial process to manufacturers of high viscous and expensive liquids. It is the best solution for processes that have numerous changeovers, long process pipelines, cross-contamination and non-recoverable issues.

Our systems are tailored to the specific requirements of different customers. By incorporating into the customer’s process, it can be completely manual, semi-automated or fully automated systems controlled by PLC and supported by either HMI or SCADA system, which is a very effective and precise solution.

IUS Pigging Systems are completely indigenous which enables us to always have an upper hand in cost thus helping our customers to achieve a quicker ROI.

Thanks to the continuous development in system components (valves, stations, manifold, etc.) the pigging technology helps the whole production unit to be more flexible:

- No product cross-contamination

- Close to nothing waste generation

- Low maintenance and easy to use

- Modularity

With an overwhelming record of supplying and commissioning pigging systems for various industries since 2005, IUS is able to deliver a specific solution for a specific need.

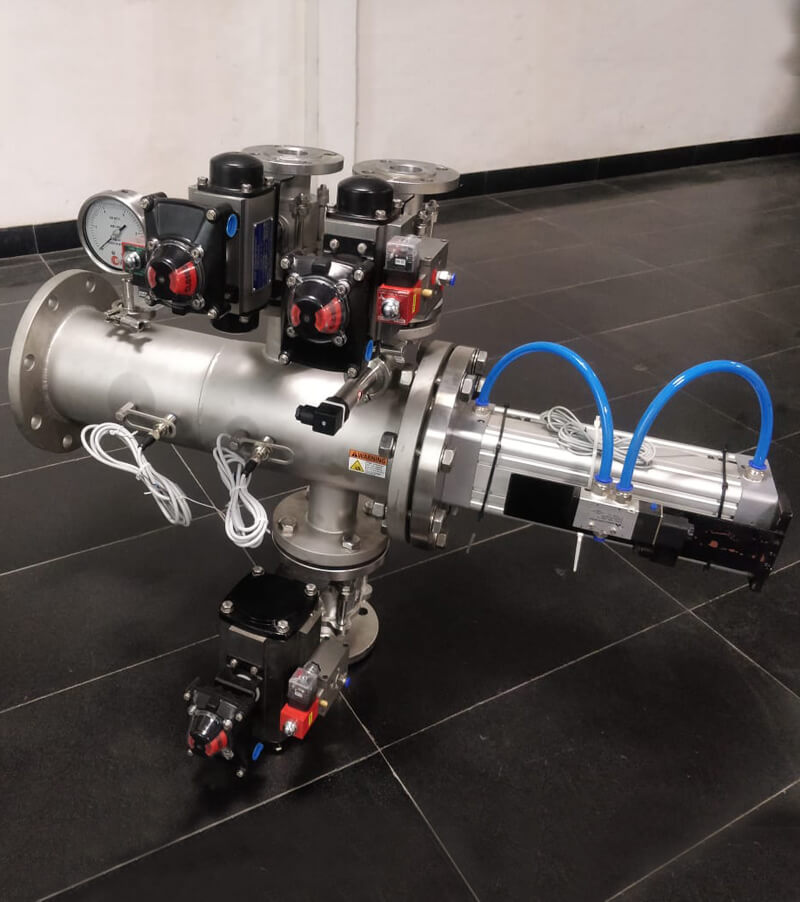

Industrial Pigging System

Hygienic Pigging System

Pigging Systems - Videos

companies that trust us

OUR CUSTOMERS

FAQ

What industries use pigging systems?

Pigging systems are widely used in various industries, including lube oil, food, beverages, paints, cosmetics, and chemicals, to maintain cleanliness and product integrity in pipelines.

What are the benefits of using a hygiene pigging system?

Benefits include reduced product waste, increased product yield, improved operational efficiency, reduced cleaning times, lower water and cleaning chemical usage, and minimized cross-contamination risks.

Can hygiene pigging systems handle different pipeline sizes?

Yes, hygiene pigging systems are adaptable to different pipeline sizes. Pigs are available in various diameters to match the specific dimensions of the pipelines they will clean.

Are hygiene pigging systems compatible with existing pipelines?

Yes, hygiene pigging systems can be retrofitted to existing pipelines as long as the pipelines are piggable. The installation typically involves adding pig launchers, receivers, and other necessary components without extensive modifications to the current setup.

What safety considerations should be taken with hygiene pigging systems?

Safety considerations include ensuring the system is correctly installed and maintained, training operators on proper usage, and following industry standards and regulations. It’s important to ensure that the pigs and pipeline materials are compatible with the products being processed to avoid contamination and safety hazards.

What types of products can be handled by a hygiene pigging system?

Hygiene pigging systems can handle a wide variety of products. They are commonly used in industries that process food, beverages, paints, cosmetics, chemicals, and personal care items.

How does a hygienic pigging system work?

The system works by launching a pig into the pipeline. The pig is propelled by air, water, or the next product batch, and it scrapes the inner walls of the pipe, pushing out leftover product and cleaning the pipeline as it moves through. The main objective of a hygienic system is to ensure that CIP of the entire system can be carried out without dismantling or removing the pig.

What are the key components of a pigging system?

The key components include pig launchers and receivers, pigs, pig detectors, valves, and control systems. These components work together to ensure efficient and effective pigging operations.

Are pigging systems safe to use?

When properly designed and operated, pigging systems are safe. They reduce the need for manual cleaning, thereby saving water and decreasing the risk of exposure to hazardous substances and enhancing overall operational safety.

Can pigging systems handle different types of products?

Yes, pigging systems can handle a variety of products. The choice of pig and system design depends on the specific product and application requirements.